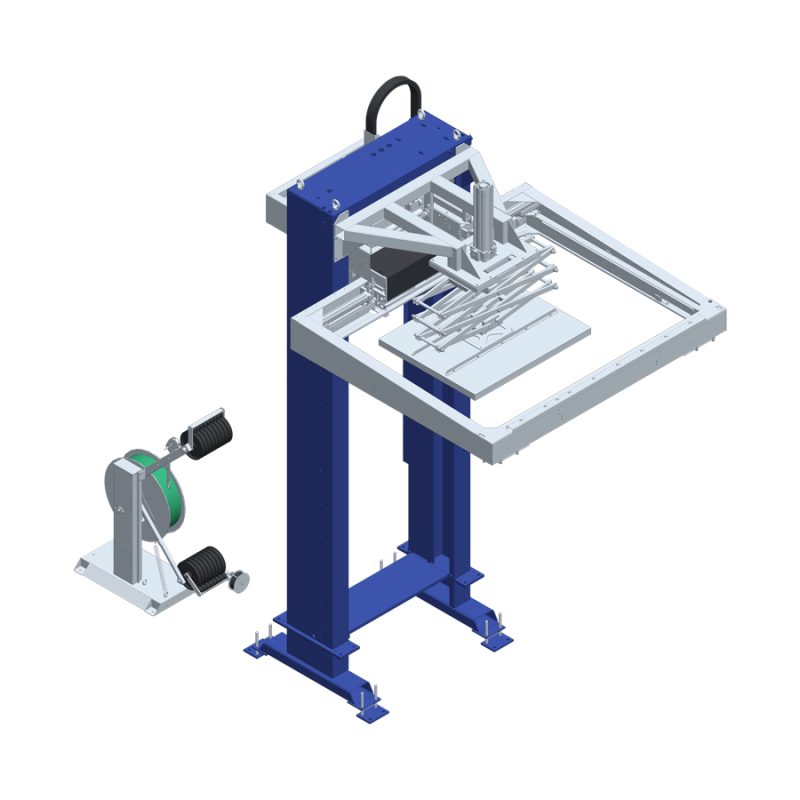

PHZUCP Horizontal Strapping System

The PHZUCP HORIZONTAL STRAPPING SYSTEM – Your Ultimate Packaging Solution!

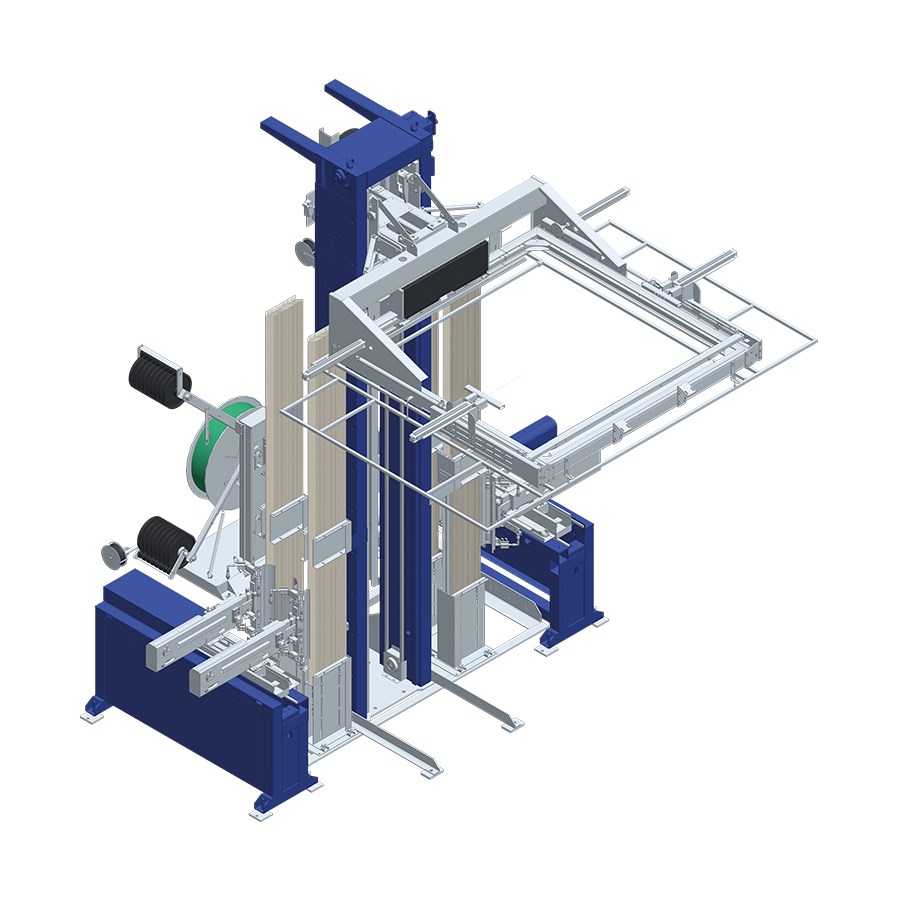

Fully-Automatic Packaging: Experience seamless bundling of packages with our state-of-the-art PHZUCP Horizontal Strapping Machine. This cutting-edge solution allows for one or more strapping operations using polyester or heat-sealed polypropylene strap, ensuring efficiency and precision every time.

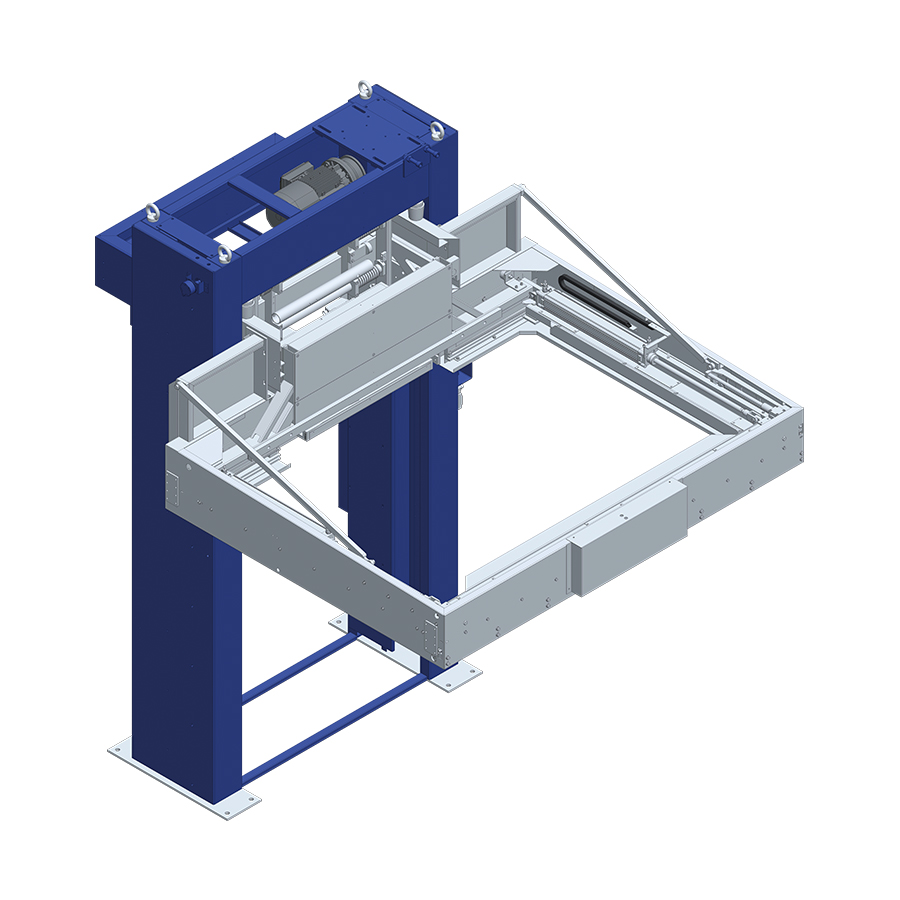

Modern Design, Maximum Performance: Engineered with the latest design criteria, our machine is equipped with advanced features for automatic strap feeding, centering, recovery, welding, cutting, and strap compensation. The tensioning device guarantees uniformity on all sides of the bundle and provides a professional finish.

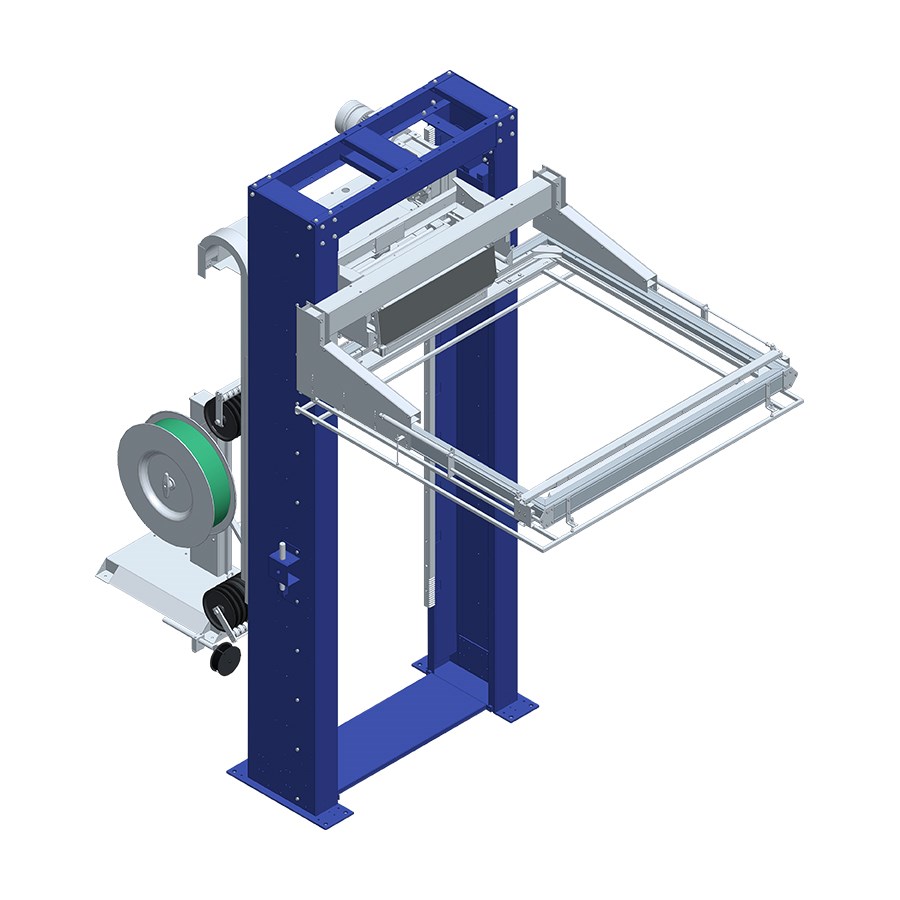

TR Family Strapping Head: Our patented strapping head from the TR family, along with strap reel holders and a user-friendly touch screen control panel, together ensure easy and efficient management of the strapping process. Experience a perfect blend of innovation and performance.

Pneumatic Squaring-Alignment Device: The PHZUCP comes with a powerful pneumatic squaring-alignment device fitted on the moving arch. This unit exerts a clamping force of up to 2500N on all four sides of the package before each strapping, creating a secure and aligned packaging process. The floating system allows for squaring and strapping of loads that are not perfectly centered under the horizontal strapping area.

Seamless Integration: Designed to seamlessly integrate into fully automatic lines, our machine can exchange signals with devices upstream and downstream or operate autonomously. Experience a new level of efficiency and productivity in your packaging process.

Upgrade your packaging game with the PHZUCP HORIZONTAL STRAPPING SYSTEM – where innovation meets performance!

- Strap type: Polypropylene (PP), Polyester (PET)

- Strap union: Thermoelectric welding

- Applicable strapping heads: Model TR1400/TR1400HD

- Reel holder: Inner ø 390 ÷ 405 mm, width 150 ÷ 160 mm

- Power supply: 400/415 V, 50Hz, Three phases

- Installed power: ~ 2 kW

- Air pressure: 5,5 ÷ 6,5 bar, ~ Nl 16/cycle

Already a Customer?

Contact Support Services.

Our team is standing by to help you.